Email: [email protected]

Precision Positioning Block Solutions for Reliable Fixture Alignment in Manufacturing and Assembly Lines

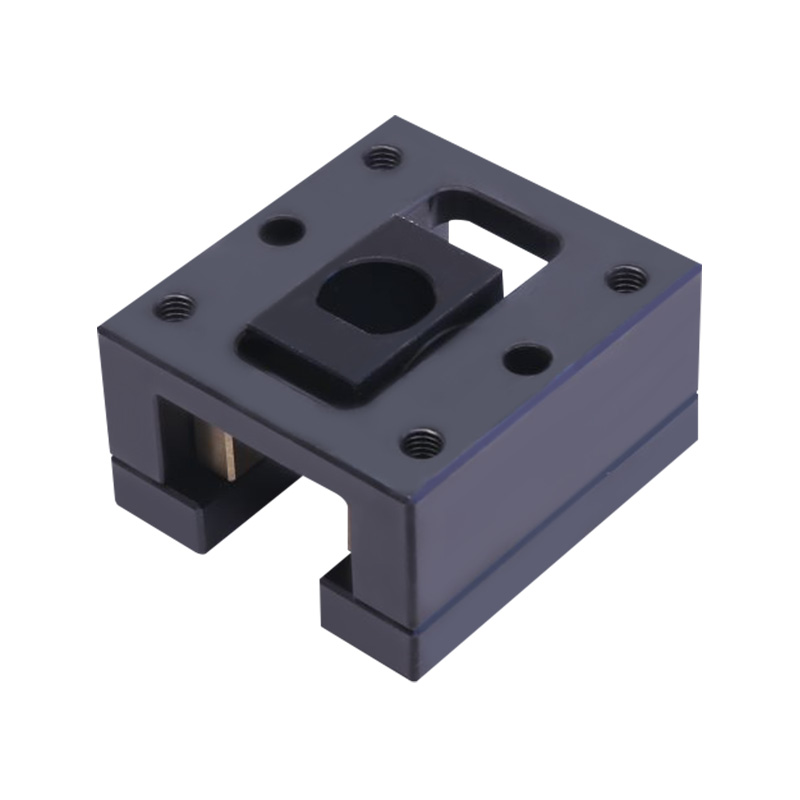

In modern manufacturing and assembly operations, accuracy and consistency are critical factors that influence production efficiency and product quality. Companies increasingly rely on advanced tooling components to maintain precise alignment and secure positioning of parts during assembly and molding processes. Among these components, the Precision Positioning Block has emerged as a reliable solution to ensure stability, repeatability, and operational safety.

Enhancing Fixture Alignment Accuracy

A key challenge in manufacturing environments is achieving precise alignment of fixtures and molds. Misalignment can advance to product defects, increased scrap rates, and potential downtime. Precision Positioning Blocks provide a robust solution by offering controlled positioning of workpieces and tooling components. These blocks are designed to fit seamlessly into existing assembly setups, allowing engineers to maintain consistent alignment across multiple cycles. By reducing the risk of misalignment, manufacturers can sustain high-quality standards while improving overall workflow efficiency.

Precision positioning is particularly important in processes that require tight tolerances. Whether in automotive assembly, electronics manufacturing, or metalworking, even minor deviations can affect the final product's performance. Integrating Precision Positioning Blocks helps stabilize components, ensuring that every part is correctly placed for subsequent operations. This stability also means fewer adjustments between production runs, saving time and reducing operator error.

Supporting Mold Safety and Operational Security

In addition to alignment accuracy, safety is a major consideration when working with molds and heavy assembly tools. Mold Safety Locks complement the functionality of precision positioning systems by preventing unintended mold movement during operation. These locks secure the mold in place, reducing the risk of accidents and protecting both operators and equipment.

Combining Precision Positioning Blocks with Mold Safety Locks creates a dual-layer safety system that balances precision with protection. While the positioning block maintains consistent part alignment, the safety lock prevents accidental displacement that could compromise the manufacturing process. This combination is particularly valuable in high-volume production lines where molds are frequently changed or adjusted, as it ensures reliable operation without sacrificing safety.

Simplifying Installation and Maintenance

One of the advantages of modern Precision Positioning Blocks is their ease of installation. These blocks are typically designed for straightforward integration with existing fixtures, eliminating the need for complex modifications. Engineers can quickly incorporate them into assembly lines, reducing setup time and lessening production interruptions.

Maintenance is also simplified due to the durable construction of precision positioning components. Materials are selected for resistance to wear, corrosion, and operational stress, allowing blocks and locks to function reliably over extended periods. Routine inspection and cleaning are usually sufficient to sustain performance, making them a practical choice for busy manufacturing environments.

Applications Across Industries

Precision Positioning Blocks and Mold Safety Locks are versatile tools used across a variety of industries. In automotive manufacturing, they ensure proper alignment of engine components, panels, and chassis parts during assembly. In plastic injection molding, these components stabilize molds and reduce variations in product dimensions. Electronics assembly also benefits from precise positioning when delicate circuit boards and components must be accurately aligned for soldering or testing.

The adaptability of these tools makes them suitable for both large-scale production lines and smaller batch operations. Manufacturers can implement them in custom setups or standard production systems, achieving consistent results without extensive engineering modifications.

Integrating Precision Positioning Blocks with Mold Safety Locks provides a reliable approach to achieving accurate fixture alignment and operational safety in manufacturing and assembly processes. By enhancing precision, reducing the risk of misalignment, and securing molds during operation, these components contribute to efficient production and consistent product quality. Their ease of installation, durability, and versatility make them valuable tools across diverse industries, supporting manufacturers in delivering reliable outcomes without compromising safety.

Get in touch

Related recommendations