Email: [email protected]

The Role of Inclined Ejector Slides in Reducing Ejection Marks and Defects

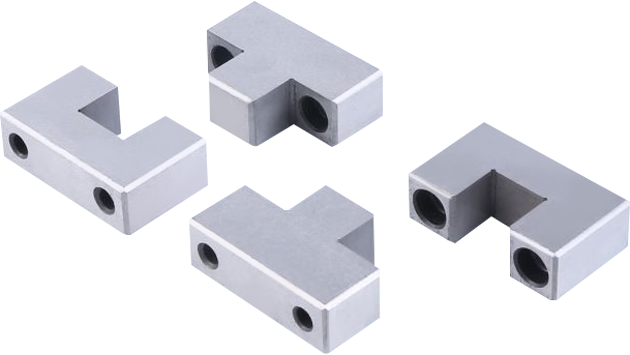

In the world of plastic injection molding, precision and surface quality are critical. Manufacturers constantly seek ways to improve product appearance and structural integrity while maintaining efficiency. One of the key innovations that has significantly contributed to this goal is the Inclined Ejector Slide. This specialized component plays a vital role in minimizing ejection marks and defects, which are common challenges in the molding process.

Ejection marks are often caused by the forceful removal of a molded part from the mold cavity. Traditional ejection systems, such as straight ejector pins, can leave visible impressions or even cause deformation on the part surface. These imperfections not only affect the aesthetic quality of the product but can also compromise its functionality. The Inclined Ejector Slide offers a more controlled and gentle ejection mechanism, reducing the risk of such defects.

The Inclined Ejector Slide operates at an angle, allowing it to follow the natural contours of the molded part. This angled motion distributes the ejection force more evenly across the surface, minimizing localized stress points. As a result, the part is released more smoothly, and the likelihood of surface damage is significantly reduced. This is particularly beneficial for parts with complex geometries or delicate features, where traditional ejection methods may fall short.

Another advantage of the Inclined Ejector Slide is its ability to accommodate undercuts and internal features that are difficult to eject using conventional methods. By sliding at an angle, it can reach areas that straight ejectors cannot, ensuring a complete and clean release. This capability not only improves product quality but also reduces the need for secondary operations, saving both time and cost.

Moreover, the Inclined Ejector Slide contributes to longer mold life. Since the ejection process is smoother and more controlled, there is less wear and tear on the mold components. This leads to fewer maintenance requirements and extended operational life, which is a significant benefit for high-volume production environments.

In terms of design flexibility, the Inclined Ejector Slide allows engineers to create more intricate and aesthetically pleasing parts without worrying about ejection-related defects. This opens up new possibilities for product design and innovation, especially in industries where appearance and precision are paramount, such as consumer electronics, automotive, and medical devices.

The implementation of Inclined Ejector Slides also supports sustainability efforts. By reducing the number of defective parts and minimizing material waste, manufacturers can achieve more efficient production cycles. This aligns with the growing emphasis on environmentally responsible manufacturing practices.

It is important to note that the effectiveness of the Inclined Ejector Slide depends on proper design and integration. Engineers must carefully consider factors such as slide angle, material selection, and alignment to ensure performance. When correctly applied, the Inclined Ejector Slide becomes a powerful tool in enhancing product quality and production efficiency.

In conclusion, the Inclined Ejector Slide plays a crucial role in modern injection molding by reducing ejection marks and defects. Its unique angled motion, ability to handle complex geometries, and contribution to mold longevity make it an invaluable component in high-precision manufacturing. As industries continue to demand higher quality and more sophisticated designs, the Inclined Ejector Slide will remain a key solution in meeting those expectations.

Get in touch

Related recommendations