Email: [email protected]

The Role of Mold Pressing Strip in Plastic Injection Molding

In the plastic manufacturing industry, precision and consistency are essential for producing high-quality parts. One critical component that supports these requirements is the Mold Pressing Strip. Specifically used in plastic injection molds, the Mold Pressing Strip plays a vital role in securing and pressing mold components together, ensuring dimensional stability and surface quality of the molded parts.

Plastic injection molding involves injecting molten plastic material into a mold cavity, where it cools and solidifies into the desired shape. For this process to yield accurate and defect-free products, the mold components must be held firmly in place throughout the molding cycle. This is where the Mold Pressing Strip becomes indispensable. It provides a reliable and consistent force that keeps mold parts tightly pressed together, preventing any movement or misalignment during the injection and cooling phases.

One of the primary functions of the Mold Pressing Strip in plastic injection molding is to maintain the dimensional accuracy of molded parts. When mold components are not properly secured, even slight gaps or shifts can result in dimensional inconsistencies. This may to defects such as flashing, warping, or uneven wall thickness. By applying uniform pressure across mold surfaces, the Mold Pressing Strip helps eliminate these issues, enabling manufacturers to achieve precise tolerances and maintain product quality.

Surface quality is another critical aspect influenced by the Mold Pressing Strip. In injection molding, the mold surface directly impacts the finish of the final product. If the mold halves are not properly aligned and tightly pressed, surface imperfections such as rough textures or seam lines may occur. The Mold Pressing Strip ensures that the mold components are held securely, minimizing surface defects and producing parts with smooth and consistent finishes.

Durability and reliability are essential characteristics of the Mold Pressing Strip in injection molding environments. These strips are typically manufactured from high-strength materials such as hardened steel or specialized alloys. This material choice ensures that the Mold Pressing Strip can withstand repeated cycles of high pressure and temperature without deformation or wear. A durable Mold Pressing Strip contributes to longer mold life and reduces the frequency of maintenance or replacement, thus supporting uninterrupted production.

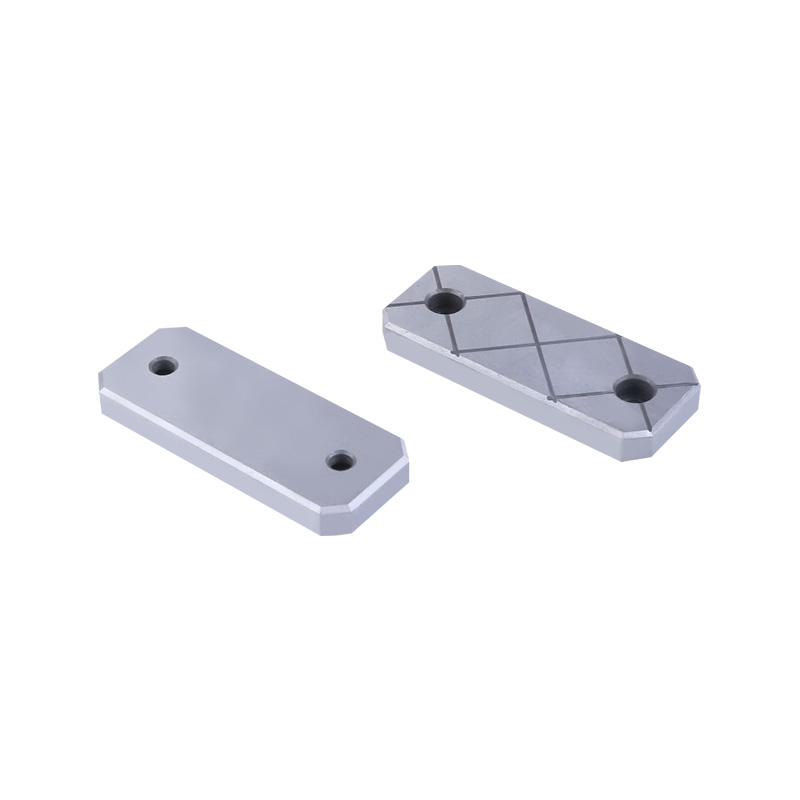

The design of the Mold Pressing Strip also plays a crucial role in its effectiveness. Many strips feature reinforced cross-sections and precision-engineered profiles that maximize their load-bearing capacity while fitting seamlessly into mold assemblies. The proper design ensures even distribution of pressing forces, avoiding localized stress points that could to premature wear or failure. This balanced pressure application is vital for maintaining mold integrity and consistent part quality over time.

Another advantage of the Mold Pressing Strip is its adaptability to various mold configurations. Injection molds come in many sizes and complexities, from simple two-plate molds to multi-cavity and family molds. The Mold Pressing Strip can be customized to fit different mold designs, providing reliable pressing action regardless of mold complexity. This flexibility makes the Mold Pressing Strip an essential component in diverse injection molding applications.

Maintenance considerations also highlight the importance of a well-designed Mold Pressing Strip. Easy installation and replacement reduce downtime during mold servicing. Since the Mold Pressing Strip experiences regular stress and wear, having a strip that can be quickly swapped out without extensive disassembly helps keep production lines running smoothly. This efficiency is valuable in high-volume manufacturing environments where minimizing downtime is a priority.

Furthermore, the Mold Pressing Strip contributes indirectly to operational safety. By ensuring mold halves remain tightly closed during injection and cooling, the risk of mold opening or misalignment under pressure is reduced. This reduces the chance of accidents involving molten plastic ejection or mold damage, protecting both equipment and operators.

Manufacturers also benefit economically from using quality Mold Pressing Strips. Consistent molding precision reduces scrap rates and the need for rework. Long-lasting strips lower tooling costs and maintenance expenses. Together, these factors improve overall manufacturing efficiency and product competitiveness in the market.

In summary, the Mold Pressing Strip is a fundamental component in plastic injection molding that supports product precision, surface quality, mold durability, and operational efficiency. Its role in securely pressing mold parts together ensures consistent results and reduces defects, which is crucial in today’s competitive manufacturing landscape. By selecting high-quality Mold Pressing Strips and integrating them into injection molds, manufacturers can achieve stable production processes and meet the demanding standards of modern plastic parts.

Get in touch

Related recommendations