Email: [email protected]

What you should know about Precision Positioning Block?

In modern manufacturing, assembly, and machining processes, achieving high accuracy is essential. One critical component that ensures precise alignment and positioning is the Precision Positioning Block. Understanding what a Precision Positioning Block is, how it works, how it differs from regular positioning blocks, and the materials used in its construction is vital for engineers, technicians, and machine operators.

What is a Precision Positioning Block?

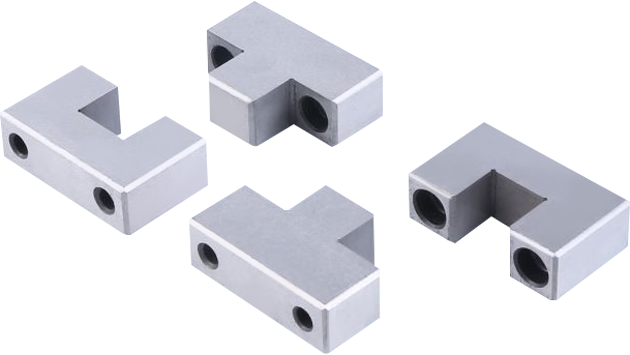

A Precision Positioning Block is a specially designed device used to secure and accurately locate components during machining, assembly, or inspection processes. Unlike ordinary supports or clamps, these blocks provide highly precise reference points that enable consistent and repeatable positioning. They are commonly used in CNC machining, mold assembly, and automated production lines where tight tolerances and exact alignment are required.

By using a Precision Positioning Block, operators can ensure that parts remain stable and aligned throughout a process, reducing errors and improving product quality. The block itself is typically compact, durable, and engineered to maintain accuracy even under repeated use.

How Does a Precision Positioning Block Work?

The working principle of a Precision Positioning Block is based on providing a fixed reference point for a workpiece or component. The block is placed on a fixture, jig, or machine bed, and the workpiece is brought into contact with its precisely machined surfaces. This ensures that the workpiece is aligned according to predetermined coordinates.

Some precision positioning blocks include adjustable features, such as threaded holes or sliding mechanisms, which allow fine-tuning of the position. Others are designed with extremely tight manufacturing tolerances, providing fixed, repeatable positioning without the need for adjustment. In either case, the Precision Positioning Block ensures that the same part can be placed in the exact location multiple times, enhancing production consistency and reducing setup time.

What is the Difference Between a Precision Positioning Block and a Regular Positioning Block?

While both types of blocks serve the purpose of positioning, there are key differences. A regular positioning block may be designed for general support or coarse alignment, often with looser tolerances and less durable materials. It may not provide the level of repeatability or precision required for high-accuracy applications.

On the other hand, a Precision Positioning Block is engineered with strict tolerance standards and high-quality materials, ensuring minimal deviation during repeated use. This precision is critical in applications like CNC machining, precision assembly, or quality inspection, where even a small misalignment can to defects or operational issues.

What Materials Are Precision Positioning Blocks Made Of?

The choice of material for a Precision Positioning Block is crucial to its performance. Common materials include:

Hardened Steel: Offers strength, wear resistance, and durability, making it ideal for high-load applications.

Aluminum Alloys: Lightweight and corrosion-resistant, suitable for applications where weight reduction is important.

Stainless Steel: Provides both strength and resistance to corrosion, especially in environments where moisture or chemicals are present.

Engineering Plastics or Composites: Used in applications where electrical insulation or chemical resistance is required, though less common in heavy machining operations.

Selecting the right material depends on the application, load requirements, environmental conditions, and required precision. A well-chosen Precision Positioning Block material ensures longevity, stability, and consistent performance over time.

A Precision Positioning Block is an essential tool in precision engineering and manufacturing. Understanding what a Precision Positioning Block is, how it works, the differences compared to regular positioning blocks, and the materials used in its construction helps operators and engineers select the right component for their applications. By ensuring accurate alignment and repeatable positioning, a Precision Positioning Block enhances product quality, reduces errors, and contributes to efficient production processes.

Get in touch

Related recommendations