Email: [email protected]

Mold Wear Block Installation and Compatibility: What You Need to Know

In modern mold manufacturing and maintenance, the Mold Wear Block plays a critical role in extending mold life and ensuring consistent performance. As mold components are subject to constant friction and pressure, especially in high-volume production environments, wear becomes a primary concern. The introduction and strategic integration of the Mold Wear Block addresses this issue effectively. In this article, we explore its installation, compatibility with existing mold structures, interchangeability, and influence on dimensional accuracy.

Installation and Standardization of Mold Wear Block

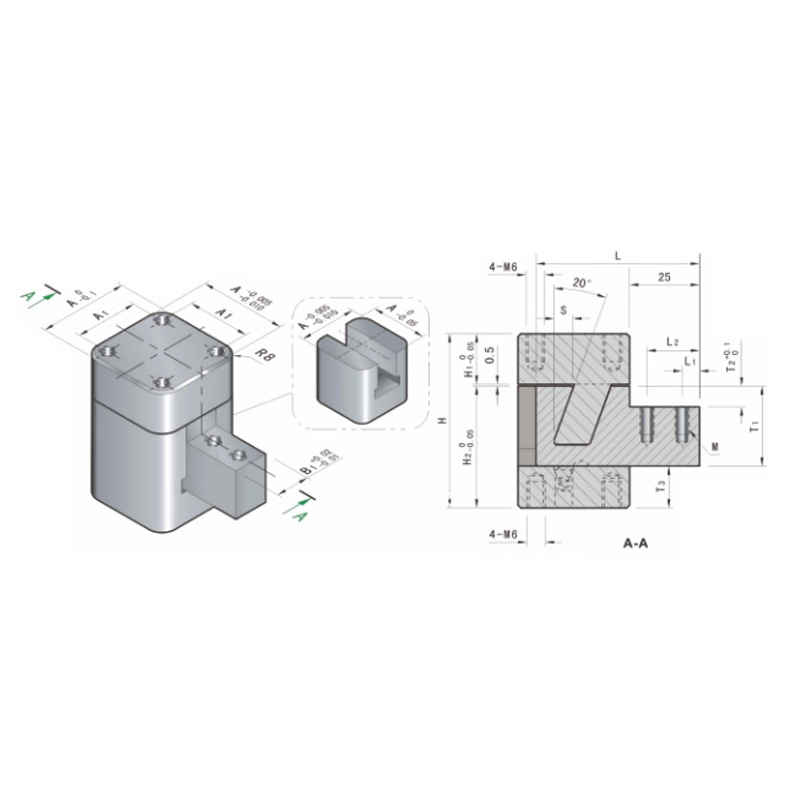

One of the practical aspects of a Mold Wear Block is its straightforward installation process. These blocks are typically designed to fit into designated recesses within the mold assembly. Manufacturers often follow industry standards when producing Mold Wear Blocks, which helps ensure consistency across different mold types. This approach supports ease of installation and alignment, reducing the time needed during initial assembly or maintenance routines.

Despite being available in a range of sizes and shapes, many Mold Wear Block products conform to modular standards. This allows mold engineers to quickly select the appropriate configuration without requiring custom machining or extensive modifications. The presence of pre-drilled mounting holes and alignment grooves further streamlines the installation, ensuring that the Mold Wear Block fits securely and functions as intended.

Compatibility with Existing Mold Structures

A major advantage of using a Mold Wear Block is its high compatibility with existing mold frameworks. In many cases, molds can be retrofitted with Mold Wear Blocks without having to redesign the entire structure. As long as the mold body has sufficient space and structural integrity to accommodate the insert, installation can proceed with minimal adjustments.

To further aid compatibility, some suppliers offer Mold Wear Block models in various material grades, including hardened steel, carbide, and even advanced alloy composites. This allows the block to match the thermal expansion and wear resistance requirements of the mold it supports. Compatibility extends not only to physical dimensions but also to operational behavior, ensuring that the addition of the Mold Wear Block does not interfere with mold function or cycle time.

Interchangeability and Replacement Process

Speed and efficiency are critical in production lines. The ability to replace a Mold Wear Block quickly minimizes downtime. modern Mold Wear Block designs incorporate features that allow for rapid removal and reinstallation. With standard screws, guide pins, or dovetail locking systems, the process often requires no specialized equipment.

In scheduled maintenance cycles, technicians can identify worn Mold Wear Blocks, remove them, and replace them with new units within minutes. This proactive replacement approach prevents more serious mold damage and avoids costly delays. In high-wear areas, some facilities even keep pre-machined Mold Wear Block sets on hand, ready for immediate use, which further enhances turnaround time.

Thanks to their standardized design, many Mold Wear Block models are interchangeable across multiple molds of similar configurations. This interchangeability supports inventory optimization and reduces the need to stock a wide variety of spare parts.

Effect on Mold Precision

Precision is paramount in mold performance. When introducing or replacing a Mold Wear Block, maintaining the exact positioning and alignment of mold components is essential. Fortunately, quality Mold Wear Block products are manufactured with tight tolerances to ensure they integrate without disrupting the geometry of the mold cavity or core.

Proper installation ensures that the Mold Wear Block does not create gaps, misalignments, or uneven pressure distribution. In fact, a well-installed Mold Wear Block can enhance overall mold accuracy by maintaining consistent spacing and guiding components along their intended path. However, it is important to conduct periodic inspections to verify that wear has not caused dimensional shifts.

Some manufacturers go a step further by offering precision-ground Mold Wear Block options, designed specifically for high-tolerance applications such as in the automotive, medical, or electronics sectors. These blocks contribute to consistent product quality, helping manufacturers meet customer expectations without compromising efficiency.

The Mold Wear Block is a key component that enhances mold durability, ensures structural integrity, and supports ongoing maintenance strategies. Its ease of installation, compatibility with existing systems, replaceability, and minimal impact on precision make it a smart investment in mold design and maintenance. As manufacturing demands grow, incorporating reliable Mold Wear Block solutions becomes increasingly important for ensuring long-term performance and cost-efficiency.

By understanding how the Mold Wear Block fits into your mold strategy, you can better manage wear-related challenges, reduce unplanned downtime, and maintain high-quality output across production runs. Whether you're upgrading existing tools or planning new mold systems, the strategic use of the Mold Wear Block deserves serious consideration.

Get in touch

Related recommendations