Email: [email protected]

The Structural Stability and Compact Design of the Precision Positioning Block

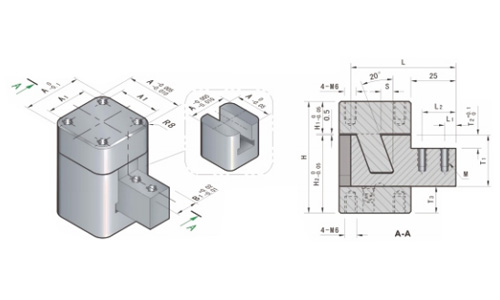

In the realm of modern manufacturing and assembly, precision and reliability are fundamental requirements. Among the many components that contribute to accuracy in these processes, the Precision Positioning Block plays a critical role. Known for its compact design and exceptional structural stability, the Precision Positioning Block is essential in preventing misalignment and ensuring consistent quality throughout production. This article explores the core advantages, applications, and technological features of the Precision Positioning Block, demonstrating why it remains a vital tool in various industries.

Understanding the Role of the Precision Positioning Block

The Precision Positioning Block is a mechanical device designed to hold or position components precisely during machining, assembly, or inspection. Unlike adjustable fixtures, it provides a fixed reference point that maintains the exact location of a workpiece or tool. This is crucial in processes where even slight deviations can to defects or assembly issues.

What sets the Precision Positioning Block apart is its careful engineering, focused on delivering both a compact footprint and strong structural integrity. These features enable it to maintain stable positioning even under demanding conditions.

Compact Design for Efficient Use of Space

One of the notable characteristics of the Precision Positioning Block is its compact design. Manufacturers often face limited space within machine setups or assembly lines, making the size of positioning devices an important consideration. The Precision Positioning Block addresses this challenge by offering a streamlined, space-saving profile without compromising on performance.

The compactness not only facilitates easier integration into various setups but also allows multiple Precision Positioning Blocks to be installed simultaneously if needed. This flexibility can be essential for complex assemblies requiring multiple points of reference. Moreover, the smaller size often translates to reduced weight, which can simplify handling and installation procedures.

Structural Stability: The Core Advantage

The main selling point of the Precision Positioning Block is its structural stability. The device is designed to resist deformation, vibration, and displacement during operation. This stability is critical because any movement or shift of the positioning block can to misalignment of the workpiece, resulting in defective parts or assembly errors.

Precision Positioning Blocks are typically manufactured using high-quality materials such as hardened steel or aluminum alloys. These materials provide the necessary strength and rigidity to withstand mechanical stresses encountered in production environments. Additionally, the design often incorporates features like reinforced ribs or integrated support structures to further enhance stability.

The structural stability ensures that the Precision Positioning Block maintains its precise location throughout the entire manufacturing or assembly process. This reduces the likelihood of errors and rework, improving overall efficiency and product quality.

Preventing Workpiece Displacement

A common issue in manufacturing is the unintended displacement of workpieces during machining or assembly. This can occur due to vibrations from cutting tools, external forces, or inaccurate clamping. The Precision Positioning Block is specifically engineered to address this problem.

Thanks to its firm construction and reliable mounting methods, the Precision Positioning Block effectively holds components in place, minimizing any risk of movement. This stable support allows machines to operate at speeds and feeds without compromising precision.

By preventing displacement, the Precision Positioning Block contributes directly to maintaining dimensional accuracy and surface finish quality. This is especially important in industries such as aerospace, automotive, and electronics, where tight tolerances are common.

Applications of the Precision Positioning Block

The Precision Positioning Block finds application in a wide variety of industrial fields. In CNC machining centers, it serves as a fixed reference for locating parts accurately before and during machining operations. This helps ensure repeatability and consistency across large production batches.

In assembly lines, the Precision Positioning Block aids in aligning components before fastening or welding. Its compact and stable design allows it to fit into robotic assembly cells or automated systems where space and reliability are crucial.

The device is also employed in quality control and inspection processes, providing a stable reference point for measurement instruments. This usage guarantees that measurements are taken consistently and accurately, supporting rigorous quality assurance standards.

Enhancing Production Consistency and Efficiency

The use of a Precision Positioning Block s to more consistent production outcomes. Because the device prevents workpiece movement, operators and automated systems can rely on repeatable positioning. This consistency reduces variability and helps maintain high standards of quality.

Furthermore, the stable design of the Precision Positioning Block decreases the need for frequent adjustments or recalibrations. This minimizes downtime, speeding up production cycles and increasing overall throughput.

Installation and Maintenance Tips

Installing a Precision Positioning Block requires attention to detail to ensure performance. It should be securely fastened to a stable base or fixture using appropriate screws or clamps. Proper alignment during installation is also essential to guarantee that the block serves as an accurate reference point.

Routine maintenance involves inspecting the Precision Positioning Block for signs of wear, corrosion, or mechanical damage. Keeping the block clean and free of debris preserves its effectiveness. If damage or excessive wear occurs, replacing the block promptly avoids compromising production quality.

The Precision Positioning Block stands as a fundamental component in the pursuit of accuracy and efficiency within manufacturing and assembly industries. Its compact design maximizes space utilization, while its structural stability ensures that components remain firmly positioned throughout various processes. By preventing displacement and enhancing consistency, the Precision Positioning Block helps manufacturers deliver high-quality products with minimal waste or rework.

As production demands evolve, the Precision Positioning Block continues to prove its value by supporting precise and reliable positioning solutions that meet modern industrial challenges. Choosing the right Precision Positioning Block can be a decisive factor in achieving manufacturing performance and quality assurance.

Get in touch

Related recommendations