Email: [email protected]

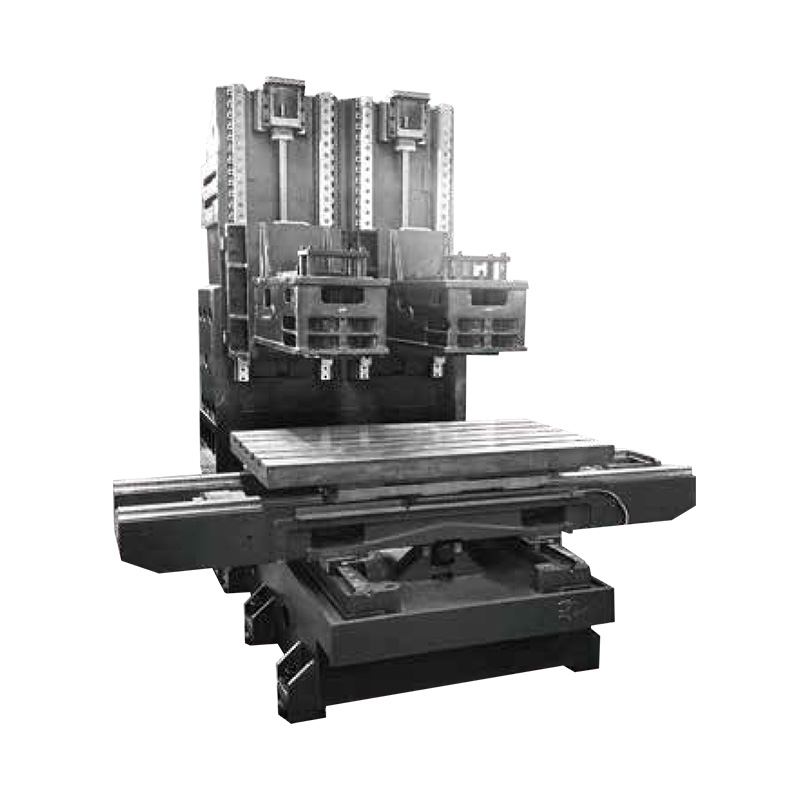

PD-620/715/720AHR Precision Molding Surface Grinder

1. The main castings of this machine are made of cast iron. After annealing, the internal stress is eliminated to ensure high precision, high rigidity, and prolong the life of the machine.

2. Wear-resistant resin sheet is affixed to the slideway of the

machine, and after precision scooping, it not only slides smoothly and is wear-resistant, it is most suitable for molding and grinding.

3. This machine adopts Taiwan's direct-coupled spindle and P4 grade super-precision roller bearings. It has low noise, high vibration and high torque at high speeds. It is most suitable for molding and grinding.

The team of Zhanmeng has adhered to the concept of a high starting point, high level, and high standard at the time of establishment. The main management and technical personnel have been engaged in the hardware stamping and mold manufacturing industry for more than 10 years, and the operating staff have followed the industry for many years and are skilled in operation.

-

Understanding the Function of the Mold Pressing Strip

Defining the Component in Manufacturing Systems A mold pressing strip is a specialized, elongated component used within various molding and ...

READ MORE -

Side Core Pulling Maker for Precision Molding

Introduction to Side Core Pulling Maker A Side Core Pulling Maker is an essential machine in the injection molding industry, designed to cre...

READ MORE -

Mold Wear Block for Durable Manufacturing

Introduction to Mold Wear Block A Mold Wear Block is a critical component in molding processes designed to protect molds from abrasion, fric...

READ MORE -

Mold Safety Lock for Industrial Protection

Introduction to Mold Safety Lock A Mold Safety Lock is a vital component in industrial molding processes designed to protect operators and e...

READ MORE -

Mold Pressing Strip for High-Precision Manufacturing

Introduction to Mold Pressing Strip A Mold Pressing Strip is a crucial component in modern molding and fabrication processes. It is designed...

READ MORE