Email: [email protected]

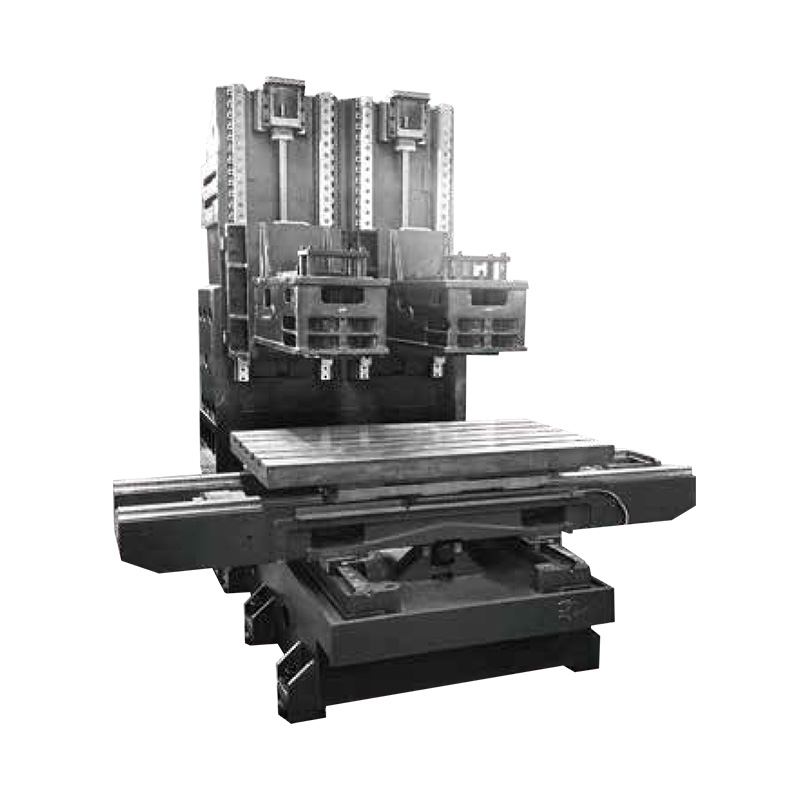

TKC Series Profile Machining Center

Characteristics of machine too

TKC profile processing center is our company's high-end CNC products. The machine tool has a unique stable and durable rigid main structure which meets the engineering requirements of double rigidity and reduced quality. lt is not only suitable for the machining of plates, shafts and precision parts, but also suitable for die machining. Accurate machining of iron, drilling,expanding,reaming, boring, tapping, two dimensional and three-dimensional curved surfaces and inclined surfaces can be continuously completed in one camping process, with high degree of automation, strong reliability, simple operation and convenience.The overall shape is beautiful, the degree of mechatronics is high, the production cycle is shortened, so that users can obtain good economic benefits.

1. This series is designed for special workpiece machine tools, ultra-long X axis travel, to meet the processing of long workpiece and shaft workpiece.

2. High quality Mihannah casting is adopted, through finite element analysis, reasonable reinforcement is arranged, so that the stability of the whole machine is higher.

3. Adopt 45 linear slide rail, lengthen slide block, high machining precision, large bearing capacity.

4. Adopt precision class large diameter ball screw, with proper precom pression, and pre-tension design at the tail.

5. Four and five axes can be added to realize turning machining of shaft parts and other parts.

6. This series standard bt40 high speed leather head, transmission stability, high speed, low noise, precise positioning.

Special configuration

Water outlet from spindle center

Servo tool magazine

Fourth axis

The team of Zhanmeng has adhered to the concept of a high starting point, high level, and high standard at the time of establishment. The main management and technical personnel have been engaged in the hardware stamping and mold manufacturing industry for more than 10 years, and the operating staff have followed the industry for many years and are skilled in operation.

-

Understanding the Function of the Mold Pressing Strip

Defining the Component in Manufacturing Systems A mold pressing strip is a specialized, elongated component used within various molding and ...

READ MORE -

Side Core Pulling Maker for Precision Molding

Introduction to Side Core Pulling Maker A Side Core Pulling Maker is an essential machine in the injection molding industry, designed to cre...

READ MORE -

Mold Wear Block for Durable Manufacturing

Introduction to Mold Wear Block A Mold Wear Block is a critical component in molding processes designed to protect molds from abrasion, fric...

READ MORE -

Mold Safety Lock for Industrial Protection

Introduction to Mold Safety Lock A Mold Safety Lock is a vital component in industrial molding processes designed to protect operators and e...

READ MORE -

Mold Pressing Strip for High-Precision Manufacturing

Introduction to Mold Pressing Strip A Mold Pressing Strip is a crucial component in modern molding and fabrication processes. It is designed...

READ MORE